ISO Certified

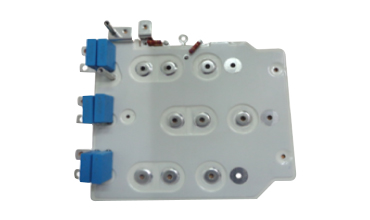

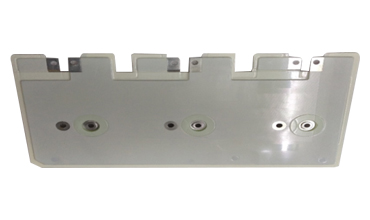

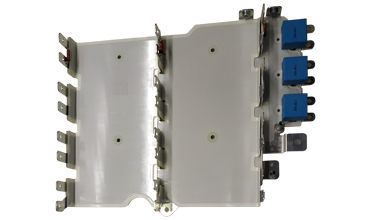

SVM - Laminated Busbars

| Various Types: |

Single conductor laminated bus bars Multiple conductor in single lamination |

|---|---|

| Material Grades : |

Lamination material Bus bond (SHELDAHL) single side adhesive coated pet films - 3.5 to 14 Mils Bus bond double side adhesive coated pet films - 3.5 to 14 Mils Inter layer insulation – FR4 or G10 glass laminate of thickness 0.3 to 2mm Mounting hard wares - made out of stainless, phosphor bronze and steel from PEM Engineering and other standards manufacturers Conductor - ETP copper 99.9% pure Insulation - Flame glass – UL 94 V-0 |

| Description: |

Laminated bus bars are manufactured under unique process control. Pet films/insulations sheets were cut using CNC machines. Conductor is placed between two insulation films and then laminated. Insulation thickness is based on Hi POT requirements. Multi-layer bus bars are fabricated with inter layer insulation where ever necessary. Copper conductors are embossed to accommodate fasteners and standoff inserts to facilitate assembly. Conductor could be Tin plated to resist corrosion and to improve contact with mating members. |

| Applications: |

Interconnection of Capacitor Links, DC Link, IGBT Power Module, Power and Measuring Components, High Current Inductors etc for various markets like Power Electronics, Wind Energy, Solar Energy, Aerospace Application, Military Application, and Transportation. |